Different Grades of Bitumen Emulsion : We are going to explain some of the important grades of bitumen emulsion and their applications below.

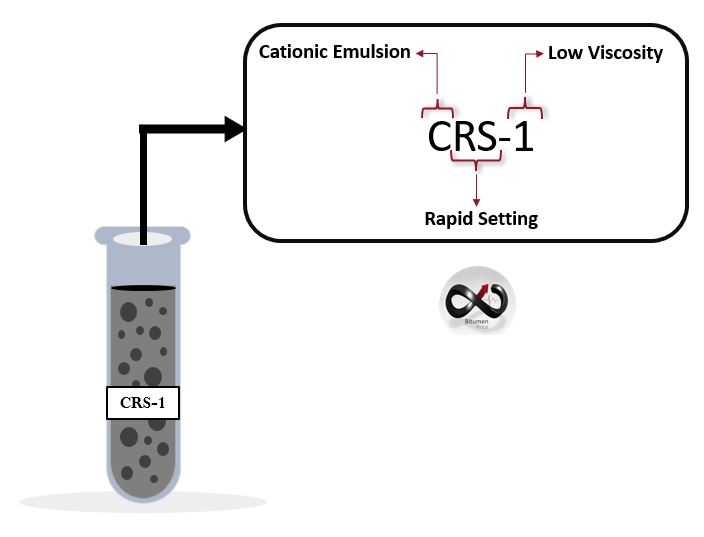

CRS-1:

According to the word “C” in the beginning, we can state that it is a cationic bitumen emulsion. “RS” is the short form of Rapid Setting time. Sand seal and tack coat are examples of fields in which they are included. The number 1 at the end refers to the low viscosity of the emulsion.

RS-1:

Since there is no “C” at the beginning of the word, it is an anionic emulsion with rapid-setting time and has a low viscosity. Furthermore, it is used in sand seals and tack coats.

CRS-2:

This is a cationic rapid setting emulsion that has high viscosity (including 65% asphalt) due to the number 2 besides the word. Chip seal, double surface treatment, triple surface treatment, cape seal, sandwich seal, and sand seal are examples of its applications.

RS-2:

This one is an anionic bitumen emulsion that sets rapidly and has a high viscosity. The application which we mentioned for CRS-2 can be named for this type, too.

MS-1:

In short, the following features can be explained about this material:

Anionic bitumen emulsion

Medium setting time

Low viscosity

Usable in sand seals

A diluted form of this emulsion can be utilized in coating jobs like fog seal and tack coat.

MS-2:

Anionic bitumen emulsion

Medium setting time

Having high viscosity

Including in Prime coating

CSS-1h:

This is a hard type of CSS-1. The number one beside the word shows that it contains about 57% asphalt. To tell you about its usage, we can name Cape seal, slurry seal, micro surfacing, seal coat, and fog seal.

The asphalt surface may suffer from corrosion and erosion. Therefore, to prevent this undesirable phenomenon, we can mix bitumen emulsion and rounded sand and after that, apply a layer of this mixture to it.

SS-1:

Anionic emulsion

Slow setting time

Having Low viscosity

Usable in Seal coat and fog seal

SS-1h:

The hard type of SS-1

The same usage of SS-1

CSS-1:

Cationic one

Slow setting time

Low viscosity

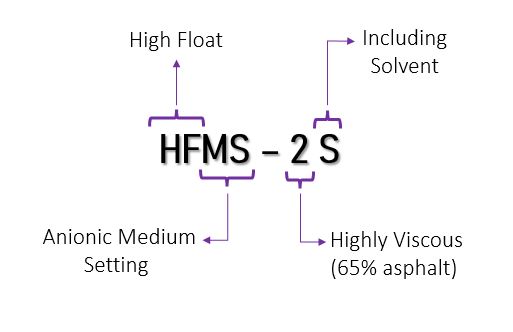

HFMS-2S:

To know about this material, please pay attention to the picture:

Notation:

The words like L, P, or S at the end of the emulsions indicate “modified emulsions”. Like: HFRS-2p, CSS-1h-p, etc.

Rate This Article