Advantages

Specification of bitumen emulsions: The most important feature of bitumen emulsion is its easy transportation even over long distances because of its lower viscosity. Furthermore, it is suitable to be used for dressing surfaces such as streets, highways, airports, roads, etc. In addition, because of its mobility and fluidity, it can penetrate easily. When the breaking process happens, the color changes and gets darker.

The other advantage that we can state is its non-toxicity. In other words, it has no harm to humans and the environment during its production, usage, and breaking. One of the positive points about this substance is that there is no possibility of ignition and fire during transportation, movement, maintenance, and implementation.

Regarding the place of their storage, we can say that vertical tanks are mostly preferred.

Shelf life of bitumen emulsion

In standard conditions, the shelf life of bitumen emulsion can be about 6 months. The shelf life is the time it can be stored in the warehouse. In general, to increase the duration of life and efficiency of this emulsion, it is better to pay more attention to its temperature conditions. The temperature at which this substance is stored should not exceed the boiling point of water. On the other hand, this temperature should not be so low that bitumen freezes. The normal range of this temperature is from 50 to 180.

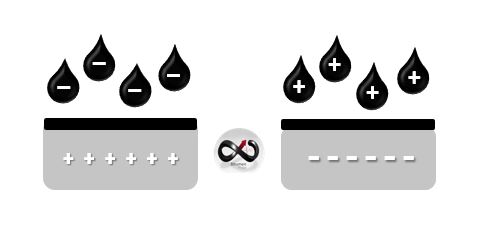

Figure 1 anionic emulsion for cationic surface and cationic emulsion for anionic surface

Notation:

In grains and aggregates, due to their type of charge, it is better not to use the same emulsion. To clarify, aggregates such as dolomite, basalt, and limestone, which have a positive charge, anionic bitumen emulsion is used. Conversely, to cover negative charge grains such as quartz, and sandstone, cationic bitumen emulsion is more suitable.

Affecting factors:

Some of the important factors that affect the quality and efficiency of bitumen emulsion are as follows:

- The quality of water

- Adding the chemical and polymer modifiers

- Characteristics of the emulsifying agents

- Type of equipment used in emulsion production

- The changes in the size of emulsion droplets

- The condition of production like temperature, pressure, and shear stress

- The type and concentration of emulsifying agent

- The diameter of bitumen particles

- The bitumen content

- Chemical characteristics of bitumen and emulsifier

Specification of bitumen emulsions:

The most important specifications of bitumen emulsions are viscosity and density, breaking, stability, and adhesiveness. There is some explanation of each one below.

Stability:

In order to make an emulsion stable, we should prevent the emulsion from settling. The settlement happens because of the difference between the density of water and bitumen. Therefore, bitumen droplets prefer to go down the system. By equalizing the density of both materials, we can prevent them from the settlement. Adding calcium chloride makes this aim happen.

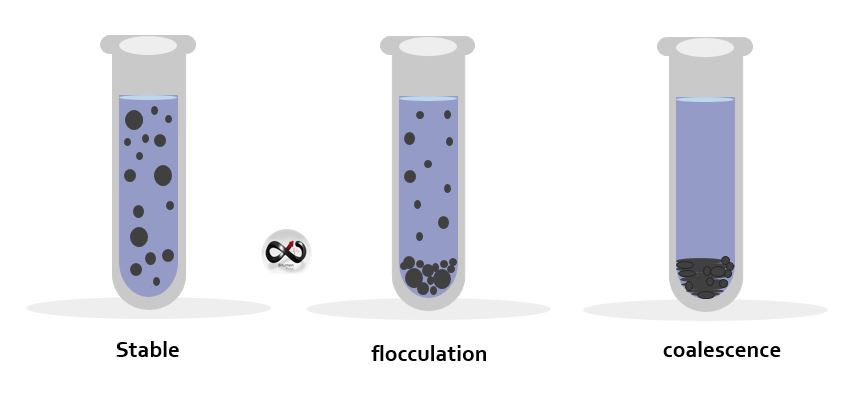

It is better to know that the settling of bitumen particles happens in two steps:

Firstly, the fines join together and make flocculation. Secondly, these flocculations connect to each other and make bigger droplets. We name this process “coalescence”.

Figure 2 emulsion settling stages

Note that in the comparison of three groups of the slow, medium, and rapid settings, we can claim that the slow setting emulsions have more stability than the medium ones and medium setting emulsions are more stable than the rapid ones.

Viscosity:

Most of the time, the emulsions, used in surface dressing, are sprayed, so their viscosity is an important issue.

The apparent viscosity is a function of temperature, shear rate, and structure of the aqueous phase. It is difficult to measure and estimate the viscosity value and behavior at a certain temperature. For instance, it can be sprayed easily and is less viscous at 90, while at 20 the viscosity value might be more. Therefore, mobility will decrease and the road surface will dry a little bit later. In cationic emulsions, which are mostly used for road construction, with the reduction of the acid amount or increase in the emulsifying agent amount, the viscosity of the emulsion will increase. Moreover, it is possible to use viscosity modifiers to adjust its value and bring it to the desired level.

In passing through the mill, the particle size distribution changes due to the increase in flow rate. To explain more, If the bitumen content in the emulsion is less than 65%, emulsion viscosity will be independent of the flow rate. Whereas, in more than 65% of bitumen content, the droplets of bitumen are closer to each other and every change in flow rate will affect the bitumen particle size distribution.

Adhesive

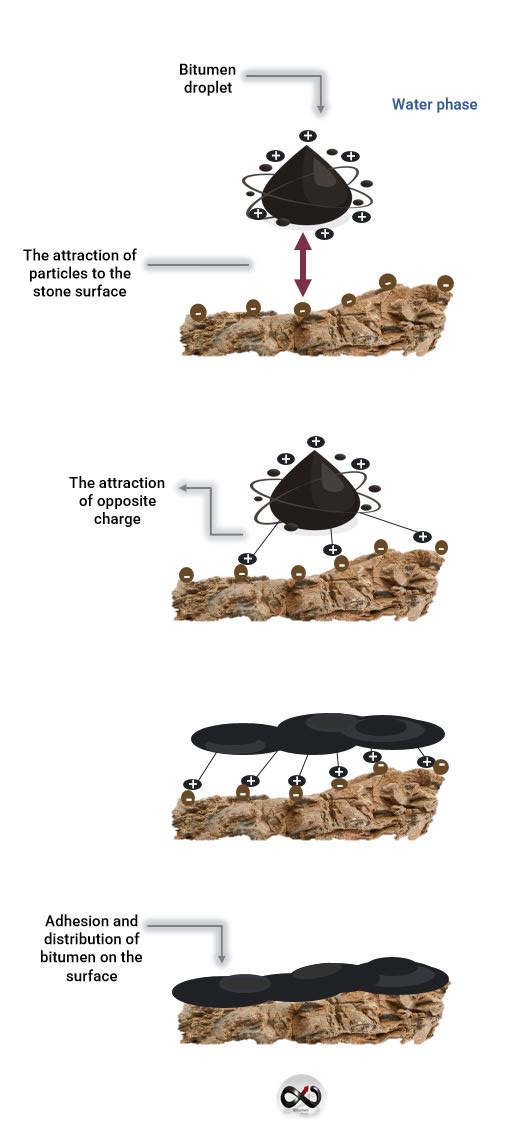

Adhesion of bitumen on stone surfaces depends on the emulsifier, the type of stone, wet or dry stone surface, bitumen compounds, and distribution of emulsion droplet size.

Breaking time

As we know, the name of a process in which water separates and evaporates from an emulsion is called “emulsion breaking”. we can categorize it into three groups:

-

Slow breaking

-

Medium breaking

-

Rapid breaking

Figure 3 the process of breaking emulsion

The parameters below are some of the factors that can affect and change the bitumen emulsion breaking:

-

The amount of bitumen:

increasing the amount of bitumen in the system causes an increase in the probability of particles hitting each other. As a result, the speed and time of breaking increase and decrease, respectively.

-

The structure of the aqueous phase:

As the ratio of acid to emulsifier decreases, the emulsion breaking rate increases. So, with the lower amount of acid and the higher amount of emulsifier, the rate of breaking will go up.

-

Particle size distribution:

the small size of bitumen droplets causes more dispersion and a slower breaking rate.

-

environmental condition:

Air humidity and temperature are effective factors in water evaporation. Deduction in temperature will cause a decrease in humidity. In conclusion, at night, when it is colder, water evaporation will stop and emulsion will be very tough, which makes it difficult to work with.

- breaking agent:

These agents can increase the breaking rate. The amount of them is important during the application. In other words, too much or too little of a breaking agent can have negative effects.

All in all, this paper was about the advantages and specifications of bitumen emulsion which we explained some important ones. We hope you all get it well.