Before Explaining the uses of bitumen emulsion, it is better to describe some sealing types and surface treatments. Then we will determine in what field each of the emulsions is used.

Seal Coat:

A seal coat is a layer that covers an existing asphalt surface. After it sets completely, we can let the vehicles pass on it. Low cost is one of its advantages. moreover, it improves the appearance of the surface and creates a homogenous layer.

Slurry Seal:

Mostly, we utilize Slurry seals in airports and streets to prevent the separating of loose grains and materials from the surface of the stone and seal it. It includes high viscous aggregates, bitumen emulsion, additives, filler, and water. Adding additives is an efficient way to have a better setting and better operation. Some important additives that we can introduce for use here are Portland cement, lime, and aluminum sulfate. uses of bitumen emulsion

It is better not to use it to fill the cracks and holes or remove the bumps. But it can increase the resistance of the surface against changes in weather conditions.

Surface Treatment:

It includes three groups:

1. One-layer surface treatment (chip seal):

This kind of dressing on the surface is cheaper than the other. It is possible to perform it for all pavements. We can count on it to enhance slip resistance and surface sealing.

It also protects the pavement of the road from the negative effects of the sun, storms, and water. Moreover, it can be used to fill some small cracks.

2. Double surface treatment:

Here, we use two layers of bitumen and material in which the grains in the bottom layer are bigger than the upper one.

3. Triple surface treatment:

It includes three layers of bitumen and material of different sizes. We know it as a flexible layer.

Notation:

in multi-layer treatments, if the operation is done well, the lifetime of the surface will be longer than one layer treatment. On the other hand, the cost will rise.

Fog Seal:

Since it is usually used as a spray, it is called fog seal or fogging. The utilization of that is to fill small fractures and cracks and prevent sanding.uses of bitumen emulsion

Sandwich Seal:

About the sandwich seal, we can state that its use is in treating slip resistance and dressing the surface.

Sand Seal:

Most of the time, we can use sand seals in the streets. It makes it easy to clean the path better. In addition, it can be applicable to weathered and sanded surfaces.

Micro-Surfacing:

We have summarized some of the features of this type in the text below:

- Kind of emulsion based on polymer

- Used in airports, highways, and streets

- Sealing, increasing the friction, and filling the holes and grooves

- Maintaining the bottom layer

- Setting quickly

- Suitable for roads and paths with heavy traffic

- Applicable at night

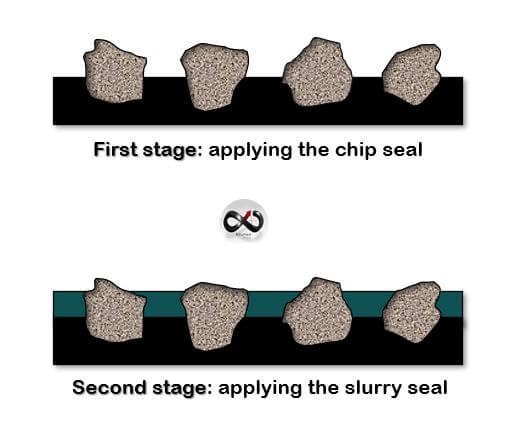

Cape Seal:

When we use the slurry seal with the chip seal, the name of this mixture will be the cape seal. In the other words, in cape seal, we use two kinds of sealing (slurry and chip seal) to fill the holes through the stone materials. Some of its features and applications are as follows:

- Removing small roughnesses

- Having relatively good durability

- Creating better friction than normal asphalts

- Reducing noise pollution

In the figure below we tried to show this type of sealing in the simplest way possible.

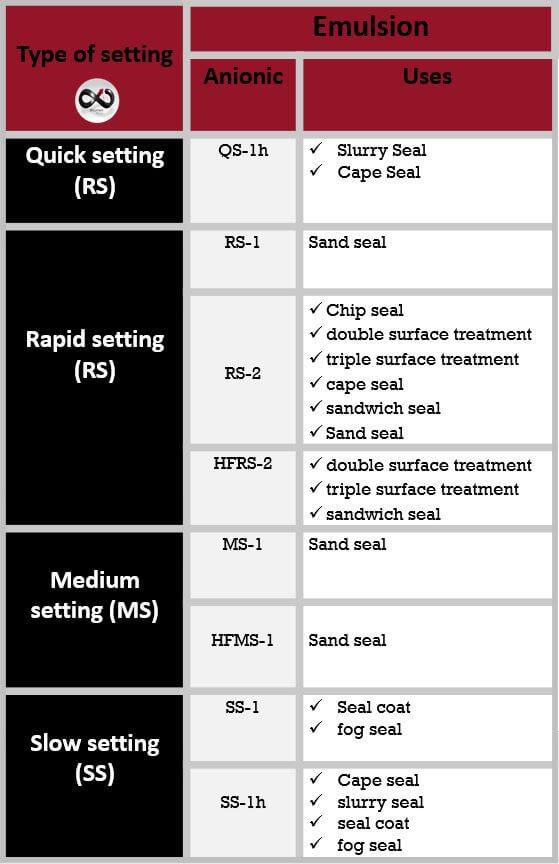

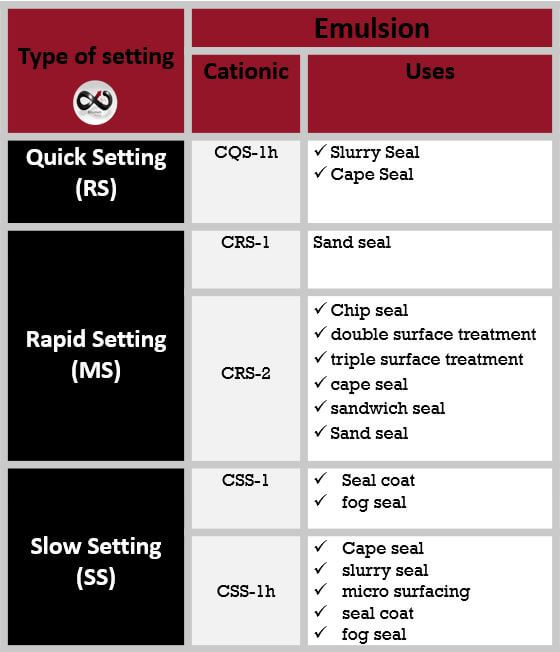

Now, by using the application in the text above, we can explain the uses of all types of emulsion (quick setting, rapid setting, medium setting, and slow setting).

Quick Setting:

These kinds of emulsions are known as micro-surfacing emulsions due to their application in micro-surfacing. In addition, we can use them in slurry seals. Nowadays, this type of emulsion is widely used in paving operations. To name some examples of this kind of emulsion, we can mention the CQS-1h and QS-1h.

Rapid Setting:

Their design is such that they can react rapidly with materials and separate bitumen from water. Surface treatment, cape seals, chip seals, sandwich seals, and sand seals are the fields they are included. RS-2, HFRS-2, and CRS-2 are examples of this emulsion that are highly viscous (according to the number 2 next to the name). Adding polymer to the modified form of these emulsions can result in producing a product that is effective for roads with heavy traffic or heavy vehicles due to its rapid adhesion.

Medium Setting:

The design of this emulsion is such that they do not break quickly when they are in contact with particles. Therefore, we can use them for various aggregates with different granularity. Sand seals and cold recycling stages are the situations where they are used. Some examples of this type are MS-2, CMS-2, and HFMS-2. The modified form of these emulsions with the polymer can cause more stability and durability. They will also be more resistant to water.uses of bitumen emulsion

Slow Setting:

They are more efficient than others. To explain more, if you want to have a stable mixture or if you want to pave highly viscous material with so many fine particles, using this type is suggested. They are not suitable for stockpile storage. Tack coat, seal coat, micro surfacing, slurry seal, cape seal, and fog seal are the cases in which these types are included. Some important emulsions from this group are SS-1h, CSS-1h, and CSS-1.