The aim of writing this paper is to answer the questions below: What is Bitumen?

What color is it? Where does it come from? Does it have any different types? are there any parameters that affect the grading? And so on. Thus, we want to get to know each of them now

What is Bitumen?

Bitumen, which is an important part of today’s world, is one of the crude oil products. Some of its physical properties can be introduced as follows:

• A liquid to semi-solid phase

• As the temperature increases, it becomes softer and black/dark in color.

• adhesive strength

• virtually involatile

•completely or nearly completely soluble in toluene

•a highly viscous and highly dense substance at ambient temperatures

Above all, the production, procedures, and crude oil properties are the cases that the original characteristics of bitumen depend on.

There are generally some heavy components like asphaltene and resin in bitumen. In other words, its different features are because of the existence of different compositions.

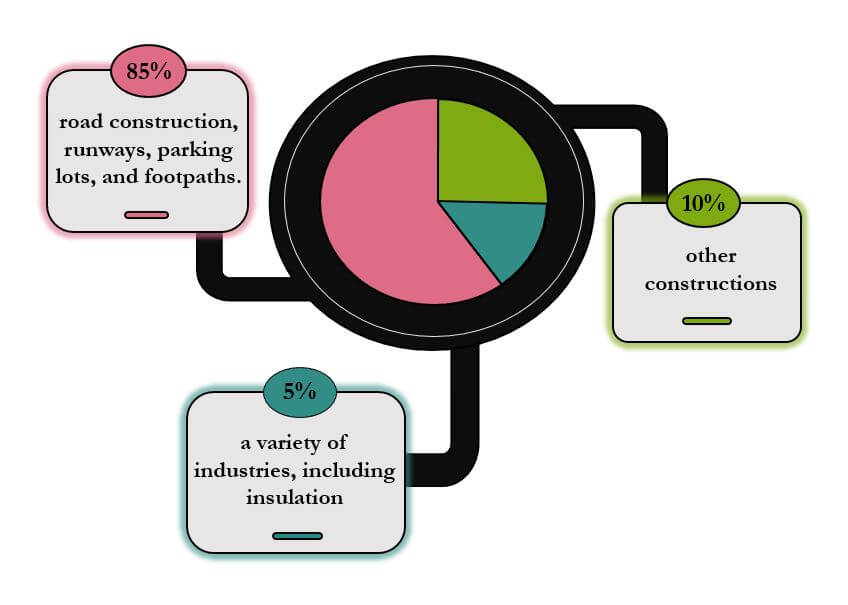

Uses:

- mostly in street construction as a solid cover

- paving and roofing fields

- binder in asphalt for streets, roads, runways, parking lots, and footpaths

- waterproofing, fixing, and protecting various materials in various businesses

Color:

It is mainly blackish-brown. To clarify, the main reason for its dark color is the presence of heavy substances such as resin and asphaltene.

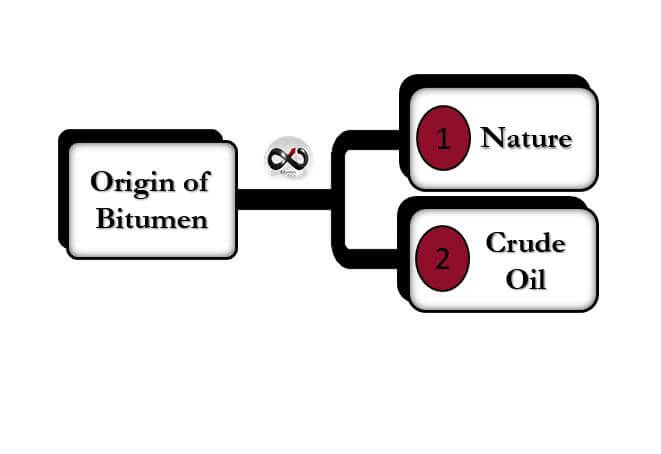

Origin

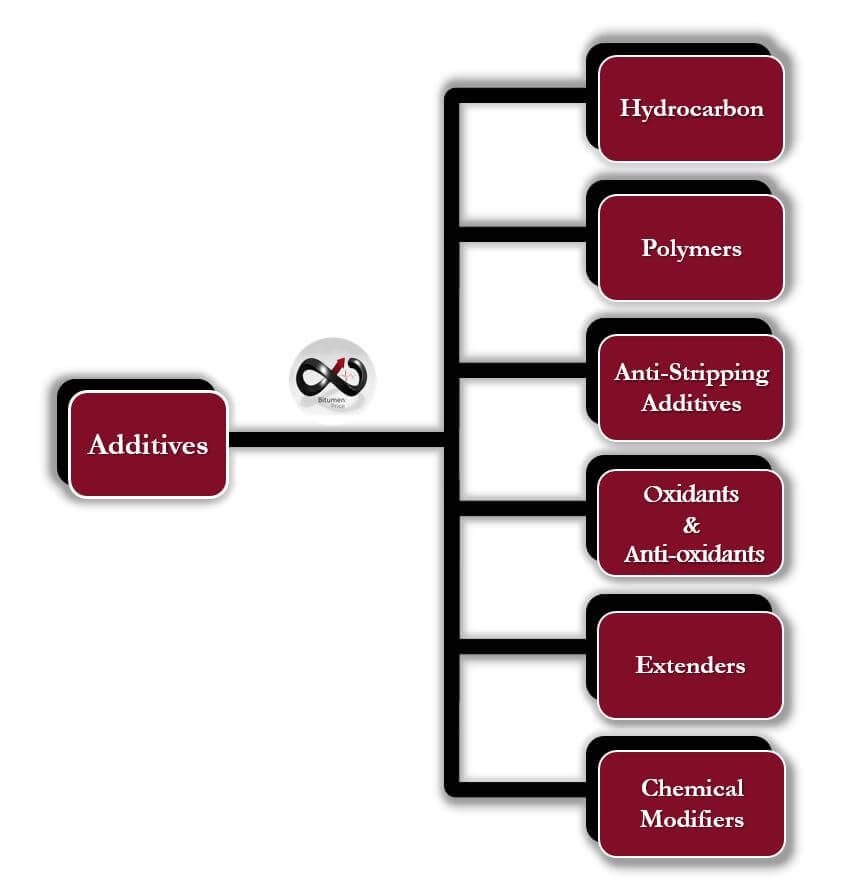

Additives:

Some modifiers and additives which can be used to improve its performance include:

Bitumen of natural origin:

Millions of years ago, some living organisms were buried in places such as sedimentary rocks, swamps, and some water habitats. Over time, some special conditions like overburden pressure and high temperature made these materials turn into residues called “natural bitumen”. Also, it can be seen in some other locations, like hills and oil lakes. Moreover, Canada, Venezuela, Oman, and the west of Iran are the most important sources of it.

In the comparison of these two, the natural origin one costs more for extraction and development than the other one.

The application of this type is to be used as an additive for:

– waterproofing coating,

– mud drilling,

– road construction (this is common in both types)

distillation of crude oil:

The bitumen obtained from crude oil or some special minerals is called pure bitumen.

Crude oil contains various compounds and functional groups which the distillation tower can separate. The residues inside the distillation tower, which are called vacuum bottoms, are transferred to be processed and converted into bitumen.

The differences between bitumen, tar, and asphalt:

In the United States, two petrochemical products, bitumen, and asphalt are synonymous. So, most people usually make mistakes in using these words while they are entirely different.

Asphalt is produced in a plant that heats, dries, and mixes grains, bitumen, and sand. On the other hand, bitumen is a substance that we can obtain in two ways؛ nature and crude oil. In conclusion, with these comments, it is not correct to use these two words interchangeably.

Similarly, tar is a dark-colored material. However, unlike bitumen, the main origin of tar is wood or coal. Since coal-based tar contains tons of benzene, it can be very harmful and cancer-causing.

Wood, as well as coal fibers, both have medicinal properties. Moreover, they can be used to treat psoriasis and kill germs.

Types of bitumen and their applications:

Various types of this black substance are obtained from various kinds of crude oil. Therefore, grading is an important matter. For grading it, we can use several standard tests which are mentioned below:

- viscosity level,

- penetration value,

- performance,

- consistency

In conclusion, penetration grades and viscosity grades are the results we can get from these tests.

Some other grades, which are classified based on their production procedure, contain bitumen emulsion, cutback, and oxidized.

Penetration grade bitumen:

The classification of bitumen penetration degrees is done by using a penetrometer apparatus and a penetration test. In short, the more the needle penetrates the surface of the bitumen, the softer it is. So, we can claim that this type is more suitable for cold weather. From the most widely used bitumen for road construction, we can name penetration one of 60/70 grade, which is mainly used as waterproof material in buildings, and then grade 80/100.

Two factors that we should pay attention to when using this type, are:

-

the average temperature of the desired area

-

its traffic amount.

Viscosity grade (VG) bitumen:

Its classification, which is based on its viscosity, is done after its production in the refinery. India is the country that has the most consumption of this bitumen.

Viscosity grade includes four different types as follows, which each have different applications.

Viscosity grade 10 or VG 20 and VG 30 & VG 40

As was mentioned at the beginning, temperature is one of the parameters that have a direct effect on viscosity. Therefore, at high temperatures, the viscosity of bitumen changes. So, viscosity grading is usually used instead of penetration.

Some of the VG bitumen advantages:

Enhancing the accuracy of bitumen in high temperatures and hot weather was the main reason for designing this grading system. A certain grade of penetration bitumen can show different characteristics at a certain temperature. In contrast, VG always has the same and constant behavior.

It is easy to predict its properties in the hottest times and also normal weather conditions.

bitumen emulsion:

It is made when tiny droplets of bitumen are mixed with water, like the emulsion of oil in water. In addition, the ability to store, transfer and transport this emulsion is very easy, economical, and safe.

These emulsions are divided into two categories: first, setting time, and second, Surface charge (cationic and anionic).

This emulsion is poured on the surface of stone or road or other similar cases. After some time, the water in this emulsion evaporates and the bitumen drops remain on the surface. Then, these drops spread on the stone surface and start to stick together.

Because of the presence of water in these emulsions, they have less viscosity. So, it is possible to use them for spraying applications.

Cutback bitumen:

Some of its characteristics are cutback bitumen :

- It is made of penetrated bitumen with organic solvents which evaporate when bitumen is used.

- low viscosity

- used when it is not possible to heat bitumen in advance to make asphalt

- Workable in cold weather

- harmful to the people and environment

Oxidized bitumen:

It is the oxidation of bitumen with hot air or oxygen into the penetration one. As a result, it significantly increases the amount of asphaltene and reduces asphaltene solubility. This type:

- is chemically stable

- has a long shelf life

- suitable for insulation, and waterproofing in dam construction projects

- impermeable to water

- usable as a corrosion inhibitor in the pipeline of the oil and gas industry

Performance grade (PG) bitumen:

In this type, bitumen is graded based on its performance at different temperatures. in other words, the higher the bitumen’s ability to tolerate high temperatures, the more suitable it is.

It is better to choose the average maximum and minimum temperature of the environment where the asphalt is made to evaluate performance more correctly.