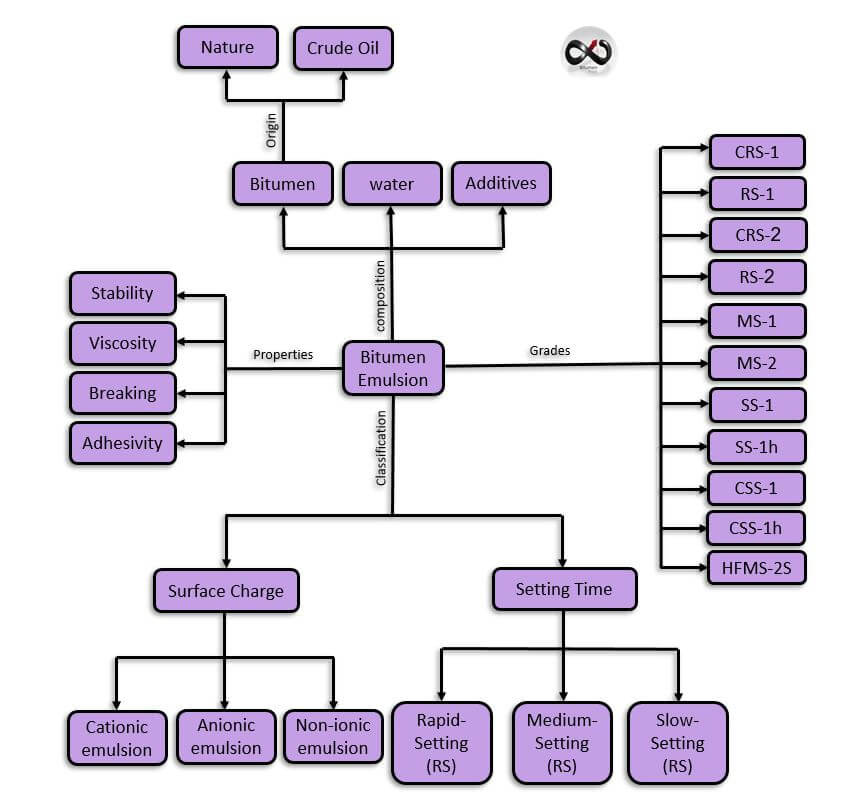

What is bitumen emulsion : In the final use of bitumen, we need a mobile and liquid form substance. Therefore, to achieve this goal, we can use one of these methods:

-

Heating

-

Dissolving in solvents

-

Emulsifying

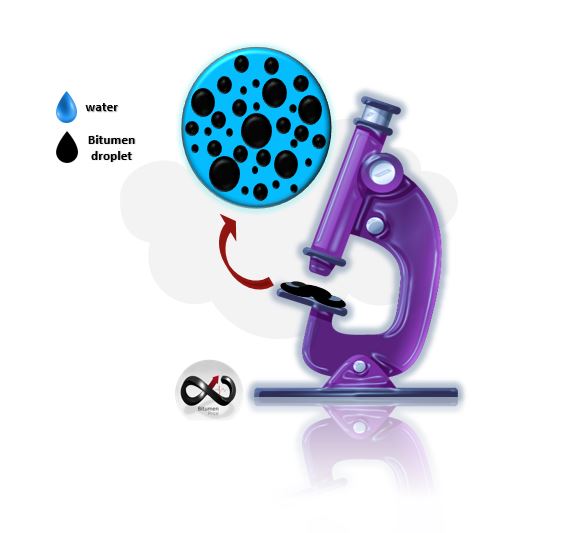

When droplets of bitumen are dispersed in an aqueous medium(water), we will name the production “bitumen emulsion”. This makes it easy to handle and transport the bitumen at lower temperatures. The average diameter of a bitumen droplet in the emulsion is 1.0–10 micrometers.

As we know, in chemistry, a “phase” is a homogeneous portion of a heterogeneous system that might contain several materials. for instance, a water-alcohol solution is a phase that includes two different components. Here, even though we have two liquid phases, bitumen fines are not mixed completely into the water. To clarify, it is a two-phase fluid system that includes two immiscible liquids, and bitumen droplets float in the continuous liquid phase.

Usually, it is possible to use some special surfactants in bitumen emulsion production. The amount of bitumen is a function of its application and its range is from 52% to 69%.

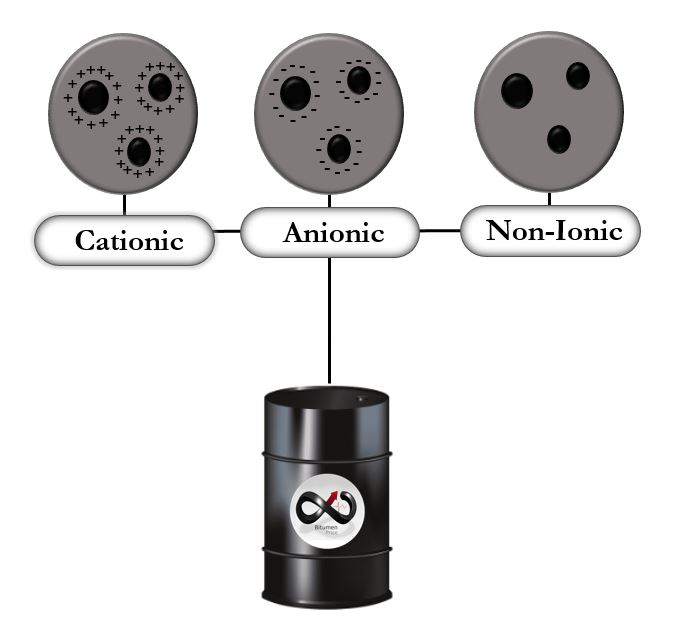

Surfactants are in three groups: cationic, anionic, and non-ionic. Usually, we can add cationic surfactants, like alkyl diamines and quaternary ammonium chlorides, in bitumen emulsion production. In general, apart from water and bitumen, there are other components like solvents, Adhesion promoters, Calcium chlorides, and sodium chlorides which can be utilized in the emulsion to provide better emulsification and reduce settlement.

bitumen emulsion types

We can categorize them based on two groups:

-

surface charge

-

Setting time

Surface charge:

mostly, we can divide this type of emulsion into the following groups:

-

cationic emulsions

-

anionic emulsions

-

non-ionic emulsions (amphoteric or neutral)

The cationic and anionic emulsions are mostly used among other ones. These names originate from the electrical charges on the bitumen droplets. Suppose we immerse two electrodes in an emulsion that contains negative bitumen particles. By establishing an electric potential between these two electrodes, bitumen fines migrate towards the anode. In this case, we name this emulsion “anionic”. On the other hand, in a system including bitumen particles with positive charges, they will migrate towards the cathode, so this emulsion is called “cationic”. In the non-ionic emulsion, the bitumen droplets are neutral so they don’t move to any of the electrodes. Utilization of this type is much less than others on highways.

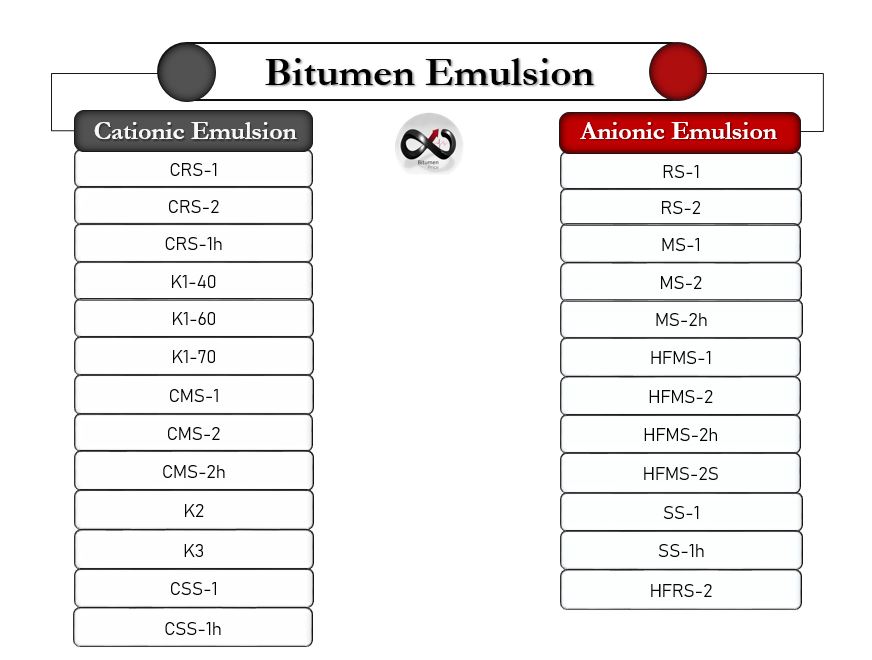

Here, there are various types of bitumen emulsions and the standard names that they have in the table:

Setting time:

We pour Bitumen emulsion on the surface of stone or roads or other similar cases. After some time, the water in this emulsion evaporates and the bitumen drops remain on the surface. These bitumen drops spread on the stone surface and start to stick together. So, according to the time that it sets and separates from water, we divide it into 3 categories and describe them one by one:

-

slow setting time Emulsion (SS)

-

Medium setting time Emulsion (MS)

-

Rapid Setting time Emulsion (RS)

Medium setting emulsion:

In this type of bitumen emulsion, when the mineral particles are mixed with the emulsion mixture on the rock surface, the water evaporation process starts.

Rapid setting emulsion:

When this type of bitumen emulsion comes in contact with the stone surface, it starts to break down quickly. Therefore, the time it takes to set and harden bitumen is very short.

properties

The most important application for bitumen emulsion is to dress the surface of roads, highways, and streets. So, it is vital to have an ideal emulsion during curing the surfaces. Some important properties of an ideal one are as below:

-

stability

-

viscosity

-

rheology

-

breaking

-

adhesivity

Grading of bitumen emulsion and factors affecting it:

By the use of international standards, we can classify bitumen emulsions which each has a special name and usage.

Penetration:

Penetration relates to the hardness and softness of bitumen emulsion. In hot weather, there is a possibility of softening and reducing the viscosity of the bitumen. So, if bitumen is harder, it will be better and it will be possible to use it at high temperatures. Pay attention that Different grades of bitumen emulsion have different penetration rates.

Viscosity:

The viscosity of the bitumen emulsion depends on the ingredients of the bitumen itself. The denser the rock, the less viscous bitumen emulsion will be sufficient.

Density:

The high density of bitumen can cause rapid settling in the emulsion. Adding a high boiling point solvent to the bitumen or increasing the weight of the aqueous phase can solve it.

Ductility

To show the bitumen’s resistance to breaking, we can perform a ductility test. In this test, the goal is to measure the extension to get how much a bitumen sample can stretch before it breaks. A ductility of more than 40 cm leads to more safety and strength on the surface of roads in heavy traffic and does not break easily. Bitumen with low ductility can crack in cold weather.

Slow setting emulsion:

These types of emulsions require a special type of emulsifier to reduce the speed of the water evaporation process. We can state that this type of emulsifier is almost stable.

Stability means that this substance must be stable and its shape and properties don’t change during:

-

transportation and movement,

-

storage

-

application

-

heating

-

pumping

Since surface curing emulsions are mostly done by spray, its viscosity in this condition is very important.

In short, there are some suggested methods to increase the viscosity of this emulsion: (note that the dispersed phase is bitumen fines and the continuous phase is liquid (water)(.

-

we can increase the concentration or the viscosity of the dispersed phase

-

we can increase the viscosity of the continuous phase

-

we can reduce the distribution range of particle size

If we do the opposite of the above operations, the viscosity of the emulsion will go down.

Emulsion viscosity doesn’t depend on the viscosity of bitumen, but if this dispersed phase is in the group of hard bitumen, which is pourable at the temperature of 10, its viscosity can affect the whole emulsion viscosity. To add more, if the bitumen content is low it can have a small effect, but if the bitumen content is high, it can affect more. Therefore, the more bitumen, the greater its effect on the viscosity of the whole system.

breaking:

The name of the process in which the water of the emulsion is lost is breaking. In the breaking, the form of an emulsion changes from the liquid phase to the continuous phase of bitumen. To recognize this issue, we should first pay attention to its color. Because in this process the color changes from brown to black and gets darker. Another layer can cover the emulsion only when it is broken. The breaking rate has three categories:

-

rapid breaking (RS),

-

slow breaking (SS),

-

medium breaking (MS).

If a truck reverses into an unbroken emulsion paver, it will lift the emulsion on its tires and decrease the effect of the tack or bond coat. Some factors such as the bitumen content, the aqueous phase composition, the particle size distribution, environmental conditions, and breaking agents influence the breaking of emulsion.

Some grades are:

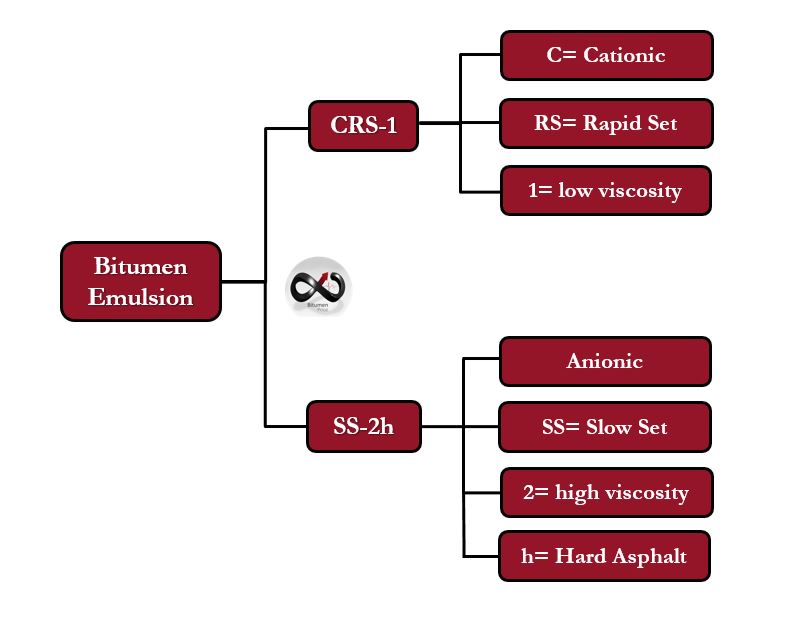

How to recognize the cationic and anionic bitumen emulsion from their names:

Conclusion

Bitumen emulsions are generally preferred to bitumen alone due to environmental conditions, weather, and economic constraints. Using bitumen emulsion reduces safety and environmental risks and saves energy and money. Adding polymers to this valuable substance improves the rheological properties of bituminous road binders to have better behavior at different temperatures.